A team of researchers including Tawfique Hasan from the Cambridge Graphene Centre of the University of Cambridge, Colin Bain from the Department of Chemistry of Durham University and Meng Zhang from School of Electronic and Information Engineering of Beihang University have made a breakthrough with printing material onto graphene.

By understanding the coffee ring effect, where the liquid evaporates quicker at the edges, causing an accumulation of solid particles that results in the characteristic dark ring, the team hope the advance will enable the fabrication of new electronics such as sensors, light detectors, batteries and solar cells.

The solution they settled on is to use isopropyl alcohol and 2-butanol to enable even distribution of ink particles in each droplet. Hasan explained, “The natural form of ink droplets is spherical – however, because of their composition, our ink droplets adopt pancake shapes.”

While drying, the droplets deform smoothly across the surface, spreading out consistently. Using this formulation, manufacturers could adopt inkjet-style printing as a cheaper strategy for the fabrication of electronic devices and sensors. The new inks also avoid the use of polymers or surfactants which hamper the electronic properties of graphene and other 2D materials.

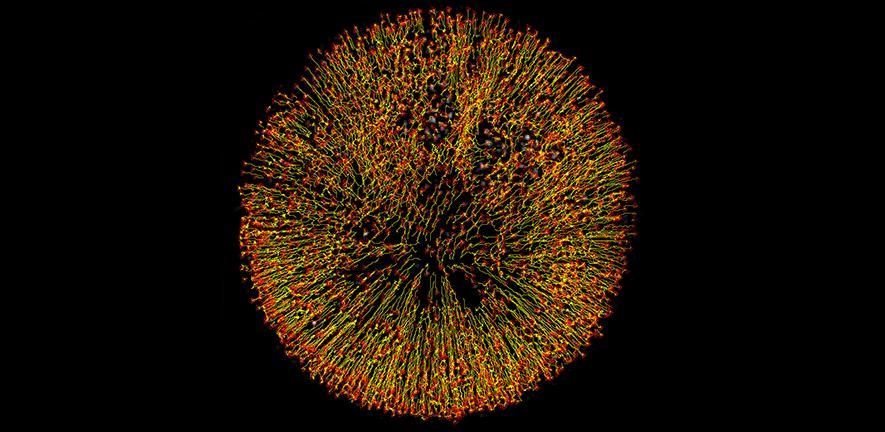

They have managed to print 4,500 nearly identical devices on a silicon wafer and plastic substrate. Devices such as gas sensors and photodetectors could be enhanced by this technique.

• Read about the Graphene Flagship's work on mobile phones here.