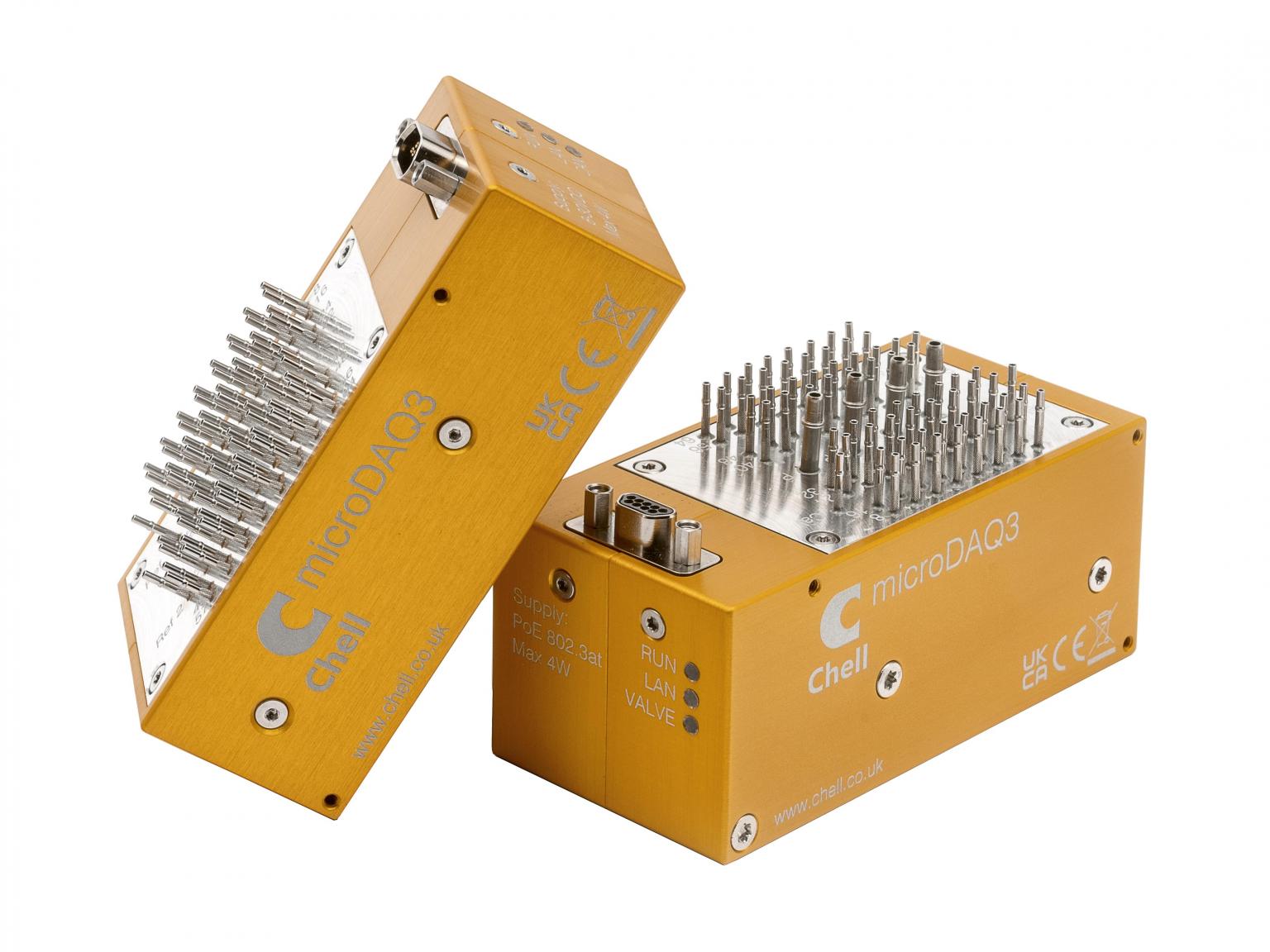

Gas measurement and control firm Chell Instruments has launched the microDAQ3, which it claims is the 'most accurate' pressure scanner currently available on the market.

The pressure scanner makes use of high-accuracy digital sensors combined with advanced calibration and temperature compensation techniques to deliver improved performance. The MicroDAQ3 also features an electrically actuated shuttle valve whilst remaining compact.

“The demanding environments in which our clients use our technology means they demand ever greater accuracy in an ever smaller, faster and more durable package,” said Jamie Shanahan, sales director of Chell Instruments. “Our team have worked tirelessly to ensure the microDAQ3 delivers across the board”.

The microDAQ3 leverages technology developed by Chell Instruments within its microDAQ and nanoDAQ ranges, such as differential and absolute measurements, embedded web server, IEEE 1588 PTP time stamping, power-over-ethernet, CAN, hardware trigger and EtherCAT.

However, the pressure scanner’s step forward in performance is largely due to the use of high-accuracy transducers which feature two 24-bit analogue-to-digital converters (ADC) per port; one for pressure and one for temperature. This highly stable output is used to almost entirely compensate for thermal effects over its wide operating range.

The increased performance of the microDAQ3 has even led Chell Instruments to adopt a new ‘metrology’ approach to specifying its accuracy.

As with all pressure scanners, the headline accuracy figure is a function of the speed of acquisition and the response of the scanner. However, most manufacturers only publish a headline specification with no information on how this is derived. For the MicroDAQ3, Chell publishes the traditional error figure (2 x sigma) together with the standard deviation and measurement uncertainty at different measurement responses. The measurement uncertainty takes into account long-term drift, any remaining thermal effects and the uncertainty of the standards used to calibrate them in the Chell UKAS laboratory. This allows the user to know exactly what the performance would be in any given situation.

“Accuracy is critical,” said Shanahan. “So, as uncertainties become ever smaller, we need to be able to pinpoint them to help our client understand and account for them.”

The microDAQ3 also offers the option of an electrically driven valve that gives the scanner a purge and re-zero facility. The valve design features precise positional measurement and motor current monitoring for deterministic positioning. It also has useful features such as counting the total number of actuations which can be used to determine if any maintenance is required in the coming years.

Despite its large specifications, Chell Instruments claims the microDAQ3 is the smallest digital pressure scanner now available on the market.

“Whatever the application, space is almost always constrained in a testing environment, so making our solutions more compact is critical to increasing their flexibility and suitability for a wide range of applications” Shanahan added.

The MicroDAQ3 is available now in ranges from 1kPa to 310 kPa (4” water to 45 psi).