Micron (µm) level stroke adjustment and self-regulating calibration allow this revolutionary jetting system to meet unprecedented levels of fluid dispensing repeatability, both valve-to-valve and after maintenance.

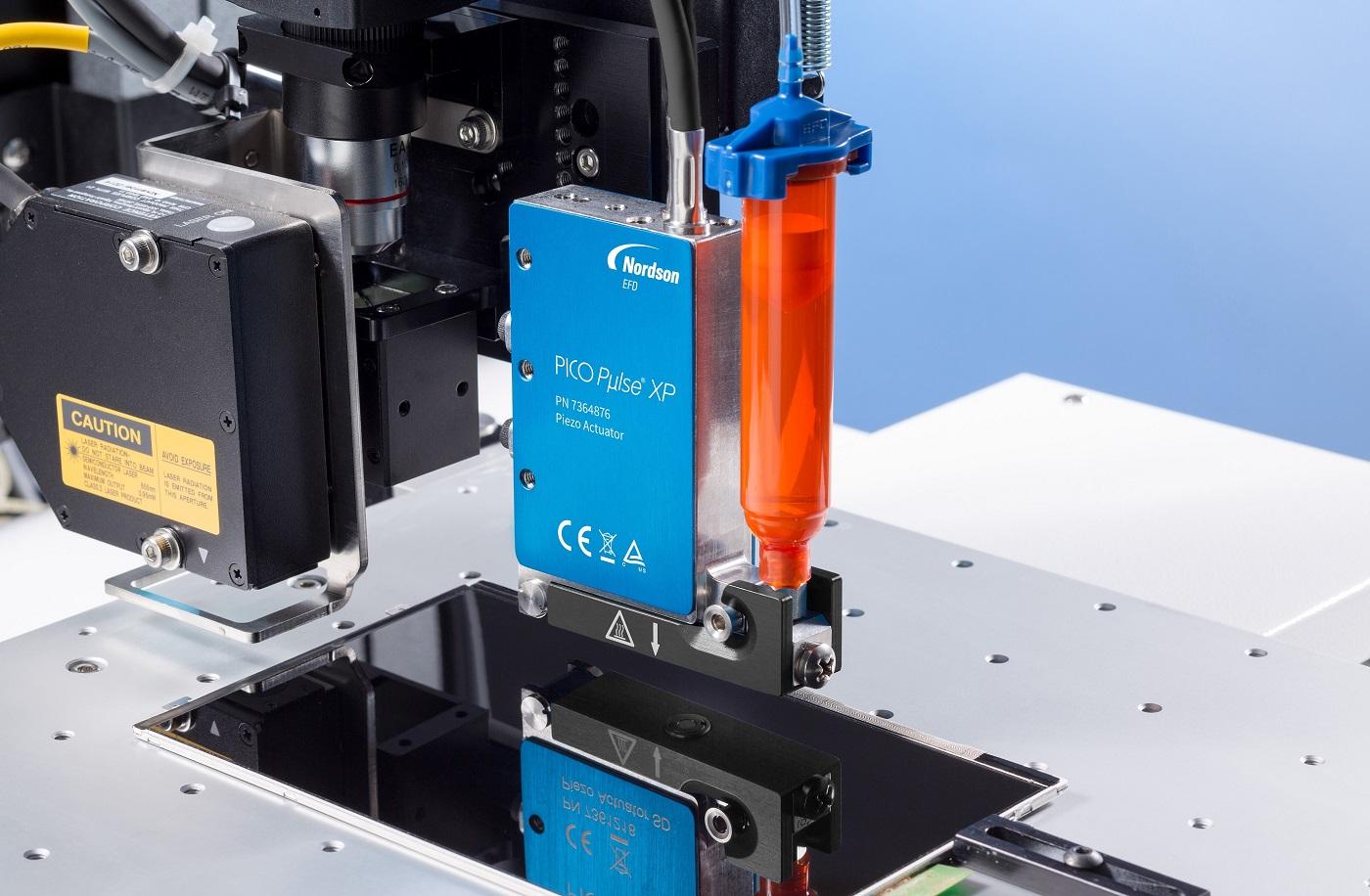

Nordson EFD introduces the PICO XP piezoelectric jetting system designed to maintain precise, repeatable non-contact fluid dispensing valve-to-valve, after maintenance, and regardless of external factors, such as temperature changes.

“This is by far our most advanced, innovative jetting technology to date,” said Claude Bergeron, Senior Global Product Line Manager, Nordson EFD. “We designed this system specifically to solve the issues manufacturers face on their production lines, especially in electronic display applications.”

Too often manufacturers see changes in dispensing performance in applications where it is critical that the correct amount of adhesive, sealant, or coating is applied consistently, every time, so they can meet consumer demands.

In these applications even a slight change in the internal geometry of the valve can affect fluid deposit repeatability.

This is why one valve may produce slightly different dispensing outcomes than another with the same dispense settings. This is also why there may be a slight change in dispensing outcomes after a valve’s fluid body is removed, cleaned for maintenance, and then returned to the valve.

The PICO XP jetting system’s unique self-regulating calibration controls for variations in fluid body tolerance to maintain the same micro-dispensing repeatability from valve-to-valve and after maintenance.

Its one-of-a-kind sustained stroke target seeking allows it to self-adjust to maintain its micron (µm) level stroke setting for long periods regardless of environmental conditions, such as temperature changes that can alter dispense results over time.

The system includes a PICO Pµlse XP jet valve and PICO Toµch XP controller with an intuitive touchscreen interface for simplified setup. It can apply micro-deposits as small as 0.5 nL at speeds up to 1000Hz (deposits per second) continuously.

The valve’s quick-release clasp allows for tool-free removal of the fluid body for simplified cleaning of the fluid path, which saves manufacturers time during maintenance. And the valve can be outfitted with several fluid bodies available with different properties and orifice sizes to meet manufacturers’ unique and versatile application requirements.